One Size Fits All: Wiseco Racer Elite 2-Stroke Pistons

Check out how the all new Wiseco 2-stroke Racer Elite pistons set themselves apart from other 2-stroke pistons here!

A first look at the 2-stroke Racer Elite pistons was seen here on Dirt Bike Magazine’s Two-Stroke Tuesday feature.

The old adage, “If it ain’t broke, don’t fix it”, might apply to wheelbarrows and wrenches, but Wiseco knows that complacency and resting on one’s laurels is detrimental to progression. The sport of motocross has been largely dominated by modern four-strokes for the past decade. Two-strokes have taken a back seat, not only in terms of bike sales, but also with regard to innovative progression.

However, take a look at any local track and you will notice that there is a groundswell movement. Two-strokes are making a comeback, thanks to their fun factor and inexpensive maintenance.

Using several different proprietary coatings, along with high-strength materials and precision machining equipment, Wiseco has created a new series of pistons. Appropriately named the Racer Elite 2-Stroke Series, these pistons are stronger, perform better, and last longer.

The Wiseco Racer Elite 2-stroke pistons are studded with industry-firsts. Read on for the full scoop.

The challenge in replacing a piston comes in choosing the proper size piston for the dimensions of the bike’s cylinder. Fortunately, Wiseco has taken the micrometer out of the equation with the Racer Elite 2-Stroke Series pistons. The secret is ArmorFit a proprietary skirt coating that allows the piston to self-adjust to the cylinder. The Racer Elite 2-Stroke Series pistons have enough clearance for the smallest cylinder, adequate clearance for the largest cylinder, and everything in between.

There is an extensive list of features and benefits that make the Racer Elite 2-Stroke Series a strong runner in two-stroke piston development. For starters, Wiseco crafted the piston out of forged 2000 series alloy. Containing up to 10 percent copper, this alloy offers outstanding heat resistance and greater tensile strength than traditional 4000 series pistons.

2-stroke Racer Elite’s are machined from a 2000 series alloy, a rarity in the 2-stroke piston world.

At the core, most two-cycle pistons are a 4000 series alloy. In a cast piston, the aluminum has roughly 20 percent silicon content. To compare, a forged 4000 series piston contains around 12 percent silicon. The 4000 series aluminum has long been the standard in piston development. However, through its life cycle, a 4000 series piston will begin to anneal and become soft. Additionally, as the piston loses its hardness, it subsequently loses its strength.

Wiseco began experimenting with 2000 series forged aluminum alloy “2618, to be exact“ on two-strokes back in the mid-1990s in a co-development project with the Kawasaki factory race team. Using their experience, Wiseco targeted the watercraft and snowmobile segments two motorsports that suffer from piston skirt collapse and detonation due to extremely high operating temperatures. It was only logical that Wiseco utilize their knowledge bank to develop a piston specially designed for two-stroke motocross machines. It wasn’t until they created ArmorPlating a protective plate coating that Wiseco could bring the 2618 alloy piston to market.

ArmorPlating Performs Better Under Stress

Truth be told, in its basic form a 2000 series alloy does not have the same wear properties as a 4000 series alloy. The 2000 series alloy, by itself, won’t work properly in a two-stroke engine without being treated with Wiseco’s ArmorPlating coating process. That’s because the material doesn’t wear the same as a 4000 series alloy, states Wiseco’s Global Powersports Product Manager, Dave Sulecki.

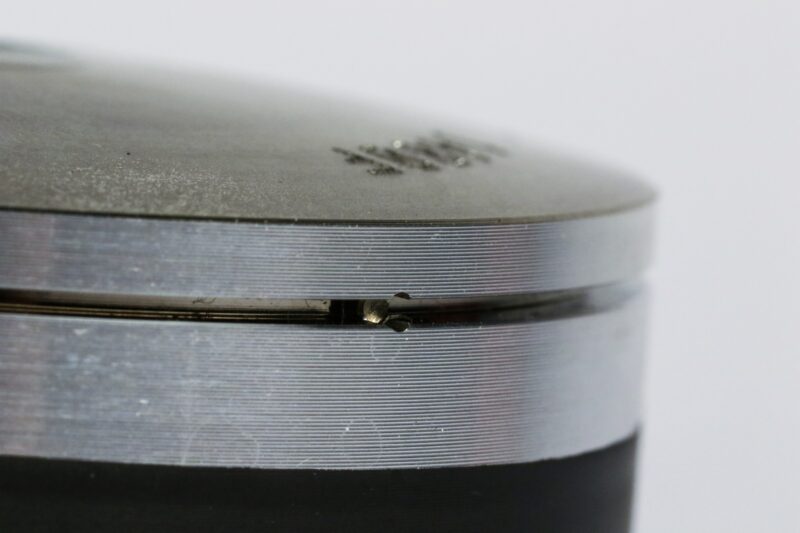

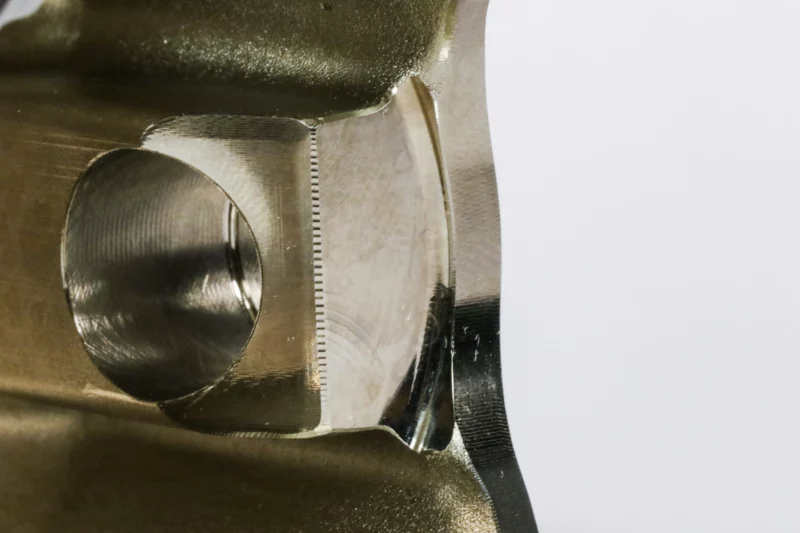

Wiseco ArmorPlating is applied to the entire piston then machined off the sides and skirts, leaving a protective coating on the crown and in the ring groove and pin bores.

What is ArmorPlating? Without letting the cat out of the bag, ArmorPlating is applied using a proprietary process. This surface treatment is the result of a chemical reaction. Unlike most coatings, ArmorPlating does not form through electrical current.

Wiseco coats their Racer Elite 2-Stroke Series pistons in ArmorPlating, but it’s not as simple as throwing the piston in a box and sticking on a price tag. Each piston undergoes a machining process to remove plating from the skirt. What remains is a coating on the piston pin bores, ring groove and crown of the piston.

An up-close look at the ArmorPlating finish.

Even though the bright, gold-colored coating is visually stunning, ArmorPlating serves multiple functions. It protects against detonation, has outstanding wear resistance, and creates better sealing with the piston ring groove. The real magic is what happens as the piston goes through heat cycles.

What’s really unique about the ArmorPlating material is that it becomes harder under temperature from combustion. Every time the piston sees a flash combustion as it’s going up and down in the cylinder the material is getting harder, states Sulecki.

Detonation can be the death knell for two-stroke engines, causing piston erosion and ring groove deformation. Even worse, detonation may dent the center of the piston crown or break right through. This is often caused by inferior pump fuel purchased at your average gas station. Inconsistencies with regard to octane levels and water content can wreak havoc on a motorcycle’s combustion chamber. ArmorPlating is a detonation defense barrier.

ArmorFit: One Size Fits All

The real beauty behind the all-new Racer Elite 2-Stroke Series piston is another proprietary process developed by Wiseco. Appropriately dubbed ArmorFit, the dry-film lubricant is applied to the skirt surface. It is the reason Wiseco has been able to condense several piston sizes into one option.

Wiseco ArmorFit skirt coating eliminates the need to use different sized pistons. Continue reading for details.

Thanks to ArmorFit, we have taken care of the need to buy the next bigger size piston. It has enough clearance for the smallest cylinder, adequate clearance for the largest cylinder, and everything in between. Provided your bore is in good shape and within tolerance of the A, B and C spec, our piston will drop right in. That’s a huge advantage, says Sulecki.

With ArmorFit, the permanent lubricant skirt surface buffs into size and will wear properly, thus taking out the guesswork. We’re trying to tell people that you don’t have to worry about choosing a specific sized piston if your cylinder is still within spec and tolerance. The ArmorFit skirt coating will do the rest, because it actually fits very tightly to the bore. It’s doing the job for you, states Sulecki.

Dave Sulecki continues, Choosing the correct piston size used to be like the wild, wild west. Manufacturers made a bevy of different piston sizes because they wanted to control the skirt diameter. It didn’t help that cylinder companies weren’t able to properly control the bore diameter. Fortunately, due to better manufacturing processes, those days are over. Consumers generally order a B-sized piston, because they are unsure of what piston size they need. Simply put, ArmorFit is the answer to a problem that has been evident since the dawn of two-cycle engines.

Aside from using an incredibly strong aerospace grade alloy, ArmorPlating for added durability and detonation protection, and ArmorFit for the perfect bore tolerance, the Racer Elite 2-Stroke Series pistons are loaded with other features. Premium quality rings enhance sealing for each application. A superfinish piston pin reduces friction for smooth operation.

Available for all popular brands, the Racer Elite 2-Stroke series pistons are the ultimate solution for two-stroke racers.

ArmorPlating, ArmorFit, precision machining, 2000 series alloy. The Wiseco 2-stroke Racer Elite piston brings a factory level piston option for the serious 2-stroke racer.