Freshen up that RZR Engine: Polaris 800 Rebuild Kits

Wiseco’s latest rebuild kits designed, developed and tested specifically for Polaris RZR, Ranger, and Sportsman 800 models deliver improved performance and durability with less hassle and cost.

Looking all the way back to the days of heavily modified Yamaha Rhinos, the recreational sport UTV segment has exploded over the last decade. Perhaps the most noteworthy model that played a big hand in transforming family off-road toys was the RZR 800 from Polaris. This platform set the stage for the high-performance, long-travel off-road cars we see today, but it also shares the same powerplant as many of its hard-working utility cousins, including the Ranger and Sportsman.

Whatever the model it was driving, this 760cc, twin-cylinder 4-stroke proved to be a reliable platform with enough grunt to get the job done or put a smile on your face. However, after many seasons of use abuse, there are plenty of these engines out there begging for a refresh.

Enter, Wiseco. Wiseco has expanded their line of reliable and affordable Garage Buddy engine rebuild kits and bottom-end rebuild kits to cover this honorable Polaris platform.

Polaris RZR / Ranger / Sportsman 800 Bottom-End Rebuild Kits

- Complete bottom end rebuild kit, including:

- Precision-machined, complete crankshaft assembly with proprietary design enhancements

- OEM-quality, complete engine gasket kit and seals

- Japanese-sourced main bearings

- Covers Polaris RZR, Ranger and Sportsman 800 models (complete model listed further down the page)

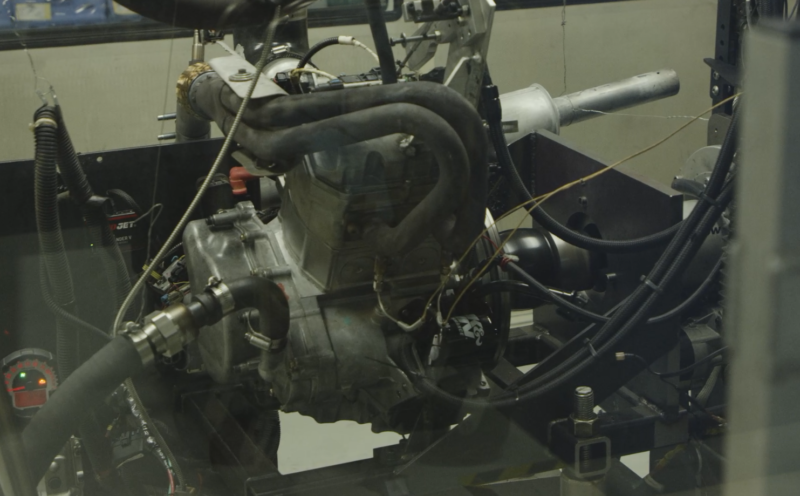

Our R&D team sourced a complete 800 engine out of a RZR 800 and did extensive testing on our in-house dyno. The team first did some dyno pulls with the engine in stock configuration to gather benchmark data, not just recording horsepower and torque, but also noting any excessive knock and detonation. They then dissembled the engine and examined its components to understand the wear characteristics of the OEM components, allowing our engineering team to design improvements for these “weak” points into Wiseco components.

The crankshaft assembly is the biggest engineering accomplishment of these kits. Going into it, the goal was to design and manufacture an assembly that could consistently deliver improved performance and longevity over the OEM counterpart. Using benchmark testing data and known points for improvement, the Wiseco Polaris 800 crankshaft uses a proprietary connecting rod design delivering optimal strength-to-weight characteristics. They are forged and heat treated for higher tensile strength and are shot peened to reduce stress risers – all together reducing the impact of engine operating stress and improving durability.

In the big end of the connecting rods, these crankshaft assemblies utilize graded big end bearings. What are graded bearings, and what advantage do they provide? Polaris 800 crankshafts use a slide-style bearing instead of a needle and cage style you might find in a dirt bike application. These slide bearings are similar to what’s used in the automotive sector, and the graded sizing allow for each crank to be built with a very specific bearing size in order to achieve highly precise bearing clearances. A fine-tuned bearing clearance ultimately translates to improved performance and longevity.

Moving onto the crankshaft gear, the material hardness of the OEM crank proved to be sub-standard to what’s commonly seen for this type of use. The gear on the Wiseco crankshaft is constructed of a material the proved to retain greater hardness, even throughout extended run time in testing.

Through experience gained both with decades of product development and first-hand use in the field, Wiseco knows a bottom-end rebuild is only as good as the main bearings that go into it. Wiseco sourced Japanese-made Koyo main bearings for use with these Polaris 800 crankshaft assemblies, helping insure longevity, smooth operation, and accurate specifications.

To aid in proper reassembly, these bottom-end rebuild kits for Polaris 800 engines include a complete engine gasket kit, not only including all the OEM-quality bottom-end gaskets and seals needed in a rebuild, but the same for the top-end as well.

Wiseco bottom-end rebuild kits are available for 2008 – 2014 Polaris RZR 800 applications as well Ranger and Sportsman 800 applications, covering both standard and 6×6. Check out the complete list of models covered below:

| Item | Make | Model | Year |

| WPC223A | Polaris | RZR 800 Ranger 800 Sportsman 800 | 2008 – 10 2010 2005 – 10 |

| WPC223B | Polaris | RZR 800 Ranger 800 Ranger 800 6×6 Sportsman 800 Sportsman 800 6×6 | 2011 – 14 2011 – 14 2011 – 16 2011 – 14 2011 – 15 |

Polaris RZR / Ranger / Sportsman 800 Garage Buddy Engine Rebuild Kits

What if your Polaris 800 engine needs a complete engine and not just a bottom end, or you’d rather freshen up everything at once? All the meticulously engineered and tested bottom end components discussed above are included in Wiseco’s Garage Buddy Engine Rebuild Kits for Polaris 800 applications, but taken a step further to include top end components as well.

In addition to the crankshaft assembly, main bearings and seals, and gasket kit, Polaris 800 Garage Buddy kits also include a forged piston kit for each cylinder, a complete top end gasket kit including valve seals, assembly lube, and an hour meter to track maintenance and the limited warranty.

Yes, these Garage Buddy Engine Rebuild Kits are covered under a manufacturer warranty against defects for up to 10 hours on the meter, or 90 days from the purchase date.

The Wiseco pistons included in these Garage Buddy kits are forged and machined in-house in Ohio, USA, providing improved durability over OEM components through greater tensile strength. These pistons were included in Wiseco’s dyno testing, done simultaneously with crankshaft testing in order to validate the complete rotating and reciprocating rebuild kit.

Wiseco engineers came up with a piston design tailored to the loads UTV and ATV engines typically experience. ArmorGlide skirt coating is applied to the piston skirts to reduce operation friction and noise, while contact reduction grooves on the top ring land help reduce expansion and avoided unwanted piston-to-cylinder wall contact. Additional, consistent power is maintained through proper ring seal aided by an accumulator groove machined into the second ring land.

Wiseco’s Polaris 800 pistons deliver a 10.2:1 compression ratio and utilize a brushed dome treatment to improve combustion efficiency. These Garage Buddy Kits are available in configurations with either standard bore (80.00mm) pistons or oversized (82.00mm) pistons. Paired up with each piston included in the kits are wrist pins, wire locks, and Japanese-made piston rings.

Much like the bottom-end gasket kit, the included top-end gasket kit provides all the gaskets and seals needed to get the rebuild done right and allows Garage Buddy Kits to be versatile enough to cover 8 different applications and 2 different bore sizes within just 4 different part numbers. Check out the complete list of models and part numbers below:

| Item | Make | Bore Size | Model | Year |

| PWR223-800A | Polaris | 80.00mm (Std) | RZR 800 Ranger 800 Sportsman 800 | 2008 – 10 2010 2005 – 10 |

| PWR223-800B | Polaris | 80.00mm (Std) | RZR 800 Ranger 800 Ranger 800 6×6 Sportsman 800 Sportsman 800 6×6 | 2011 – 14 2011 – 14 2011 – 16 2011 – 14 2011 – 15 |

| PWR223-820A | Polaris | 82.00mm (+2mm) | RZR 800 Ranger 800 Sportsman 800 | 2008 – 10 2010 2005 – 10 |

| PWR223-820B | Polaris | 82.00mm (+2mm) | RZR 800 Ranger 800 Ranger 800 6×6 Sportsman 800 Sportsman 800 6×6 | 2011 – 14 2011 – 14 2011 – 16 2011 – 14 2011 – 15 |

Whether it’s a Polaris RZR serving up family fun or a Ranger or Sportsman relied on to get work done, Wiseco Bottom-End Rebuild Kits and Garage Buddy Engine Rebuild Kits can help restore and improve performance and reliability for less hassle and cost over OEM components.