Top 3 Signs Your Dirt Bike or ATV Needs a New Clutch

The clutch system is the most important connection between your hand and the rear wheel, as far as controlling the machine. When working properly, most riders don’t give their clutch a second thought. However, the importance of the clutch quickly snaps into focus when there’s a problem with the system.

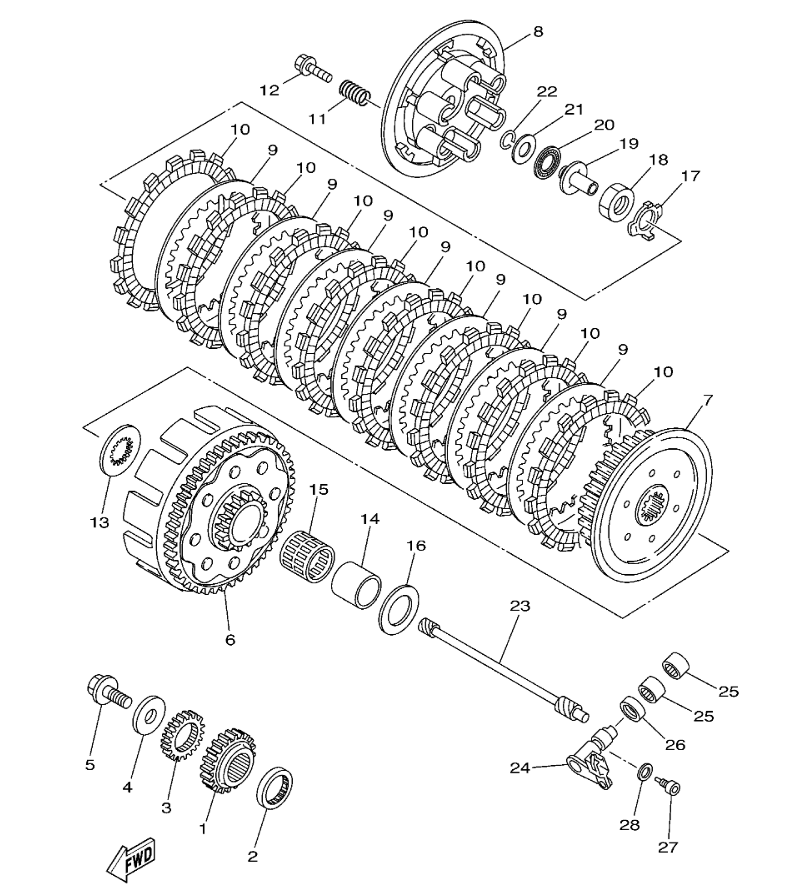

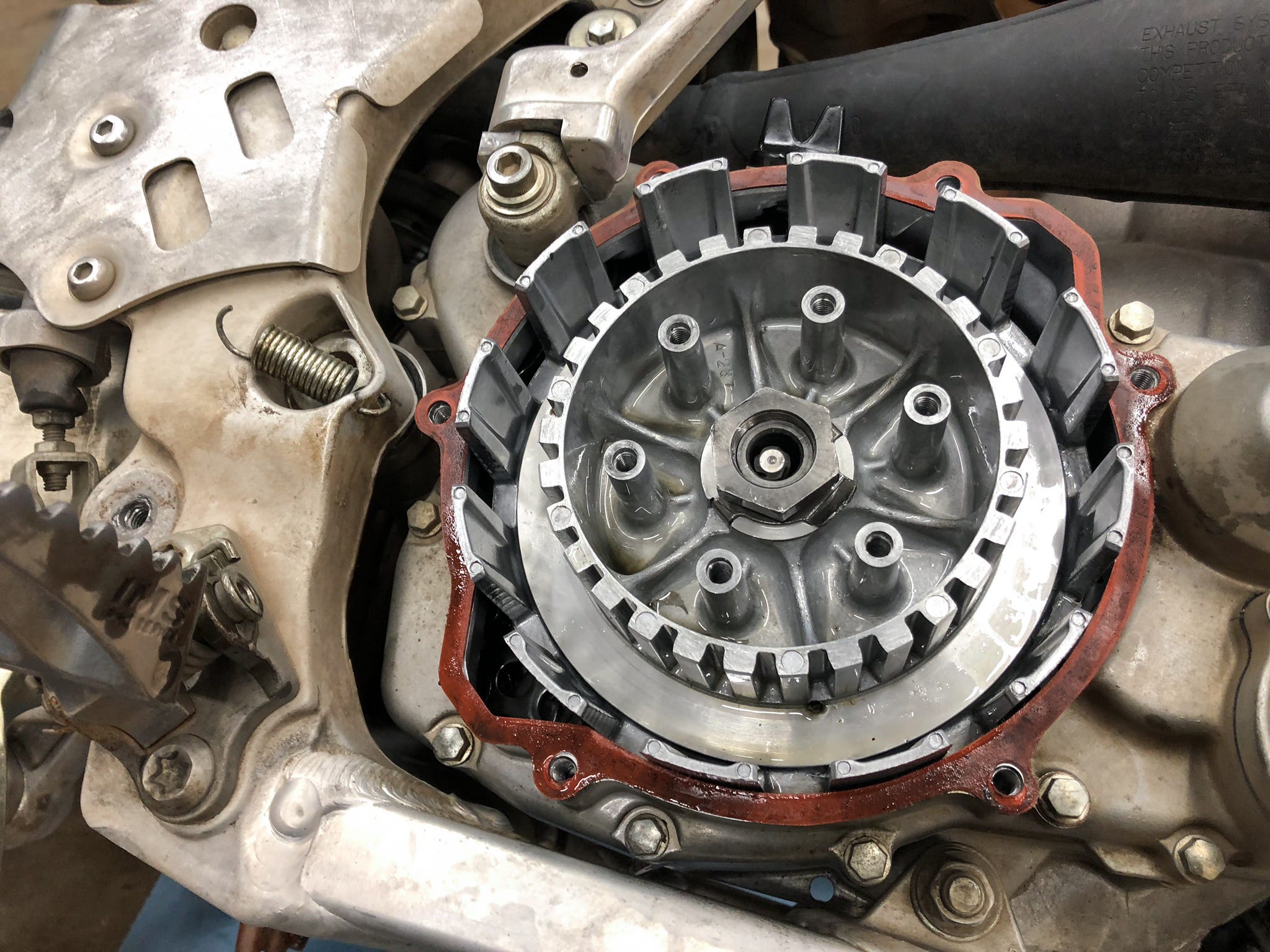

A clutch is an engineering marvel. Imagine you are on the starting line waiting for the gate to drop. You start your bike and pull in the clutch. What follows is a chain reaction of events. A series of moving parts transfer that load down to the clutch, where the pressure plate is pushed away from the clutch pack, basket, and inner hub. At that point, there is a disconnection between the transmission and crankshaft.

With the clutch disengaged, you click the shifter into gear. The gate drops, and you quickly release the clutch lever. The clutch springs force the pressure plate to squeeze the friction and drive plates together, causing the clutch basket and inner hub to synchronize. At that point, the energy generated inside the combustion chamber is carried through the transmission and to the countershaft sprocket, which then transfers the load to the rear wheel. Without an operating clutch, you would be sitting on the starting line as the pack raced away.

Suffice it to say that your clutch is a vital piece of the overall puzzle. And, like most parts on your bike, it won’t last forever. Fortunately, there are three general indicators that your clutch is not working properly. You don’t need to be deft or dexterous to determine whether your drive system is giving up the ghost. The only necessities are a handful of tools, basic mechanical knowledge, and a good sense of smell. In this article, we delve into the symptoms, causes and solutions for the most common clutch problems so you can get back to riding.

Sign #1: Slipping Away

Symptoms:

A slipping clutch is quickly recognizable when you’re twisting the throttle with reckless abandon while the machine is in gear, yet the rear wheel isn’t rotating in unison with the engine’s rpm. If you’re wound out in third gear and only accelerating at a snail’s pace, then something is wrong. You may also be able to notice a vague feel at the clutch lever. Either of these symptoms suggest that the internal clutch components need to be inspected for wear.

Causes:

When a clutch is performing optimally, the drive plates and friction plates are pushed together during clutch engagement (i.e. when the clutch lever is let out). The connection causes the rotation of the clutch basket and the inner hub to synchronize and work as one unit. However, as the plates begin to wear out, the clutch plates will slip against each other instead of grabbing. This prevents the transfer of energy from the engine to the transmission. Unfortunately, clutch slipping is inevitable, even if you aren’t a clutch abuser. Clutch plates wear out over time as a result of rubbing when the clutch is engaged.

It is also possible that the clutch springs have lost their tension. When this happens, the springs aren’t strong enough to effectively pull the pressure plate against the clutch pack. Just as with clutch plates, clutch springs do not last forever.

Solutions:

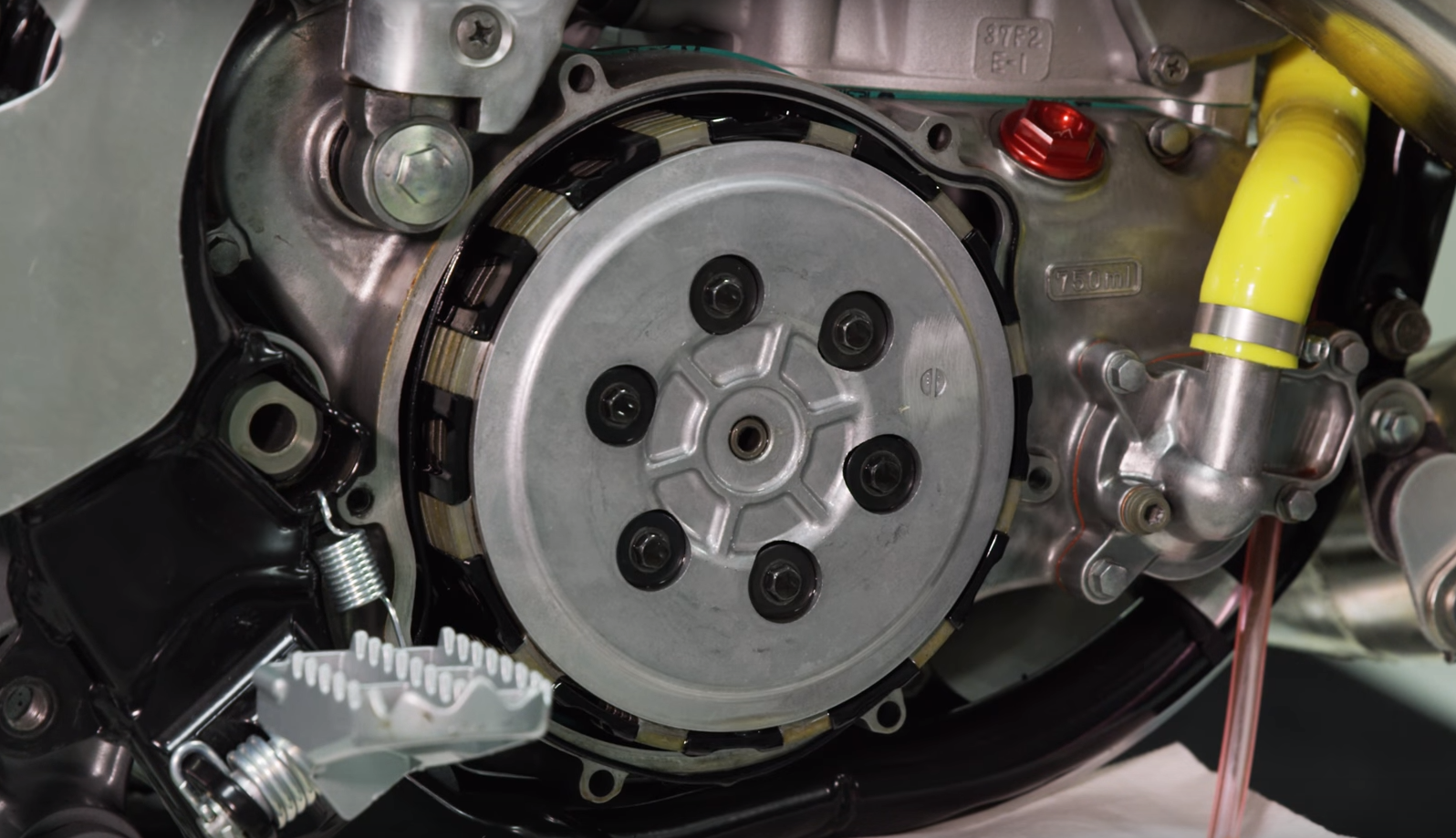

When you experience clutch slippage, you’ll need to inspect the drive and steel clutch plates, as well as the clutch springs. To quote Dave Sulecki, Wiseco Powersports Engineer, œIt’s very easy to access the clutch on all the new bikes. You can literally lay the bike over on its side, pop off the clutch cover, and start inspecting the components.

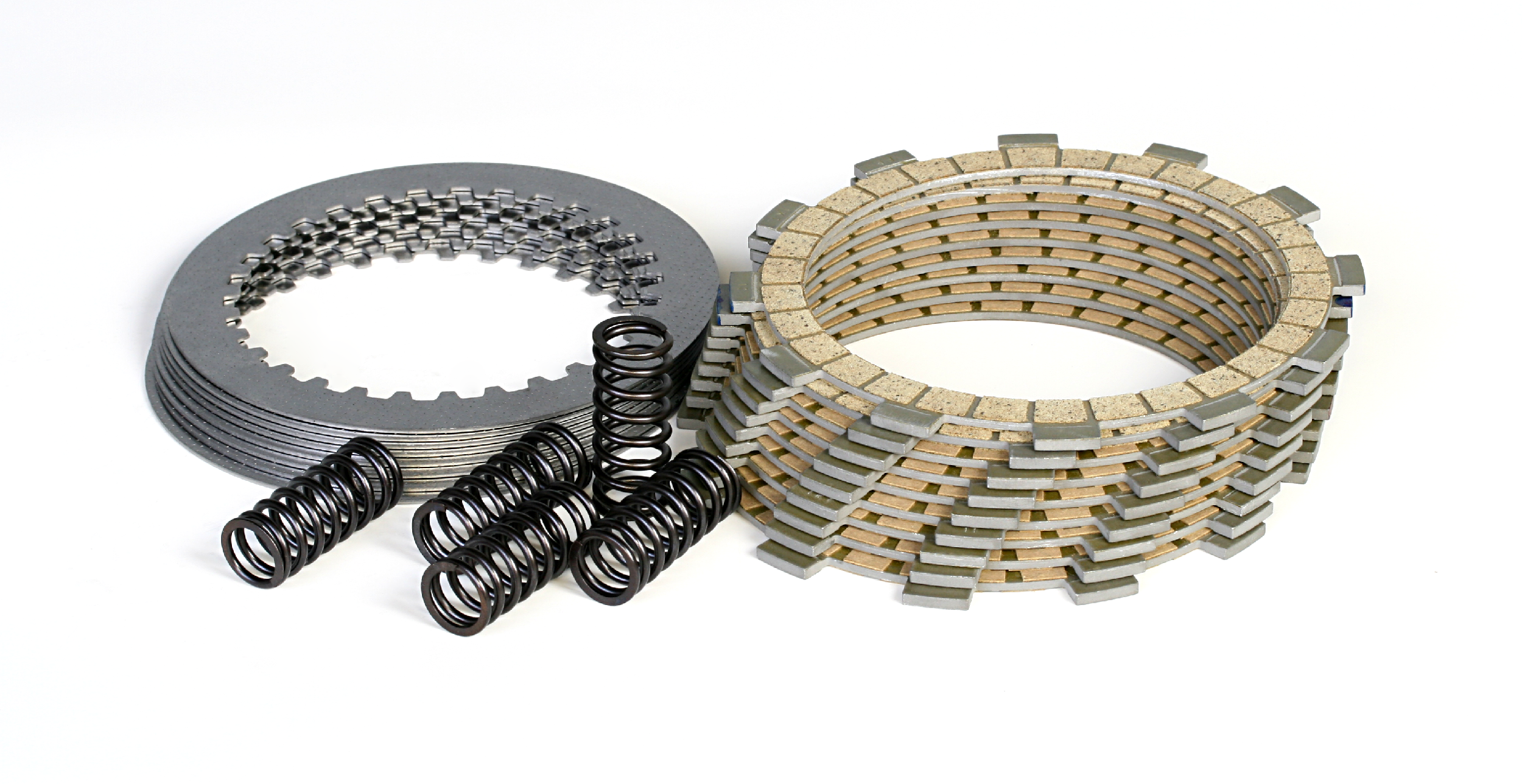

Using a vernier caliper or micrometer, measure the thickness of the steel (or aluminum) drive plates, and the fiber plates. Consult your owner’s manual to find the recommended specs. Be sure to also check the free length of the clutch springs. It’s a good idea to replace the drive and fiber plates, as well as the clutch springs.

Replacement clutch components both in individual components and clutch pack kits are readily available through aftermarket companies like Wiseco. Replacing your fiber and drive plates at the same time is common practice, and when springs are required as well, all these components are available in kits with fibers, plates, and springs in one box. Each kit is built to OEM specifications and far less expensive, and Wiseco clutch springs feature a stiffer rating for a more positive clutch engagement.

Find Wiseco clutch components for your bike or ATV here.

Sign #2: Creeping & Bad Smell

Symptoms:

The machine is emitting a foul burning smell that could strip paint off a wall. The stench might be so pungent that it’s evident after pulling into the pits. Generally, though, the smell is noticeable after removing the clutch cover. You may also notice your bike creeping forward with the clutch pulled in and the transmission in gear, no matter how much you adjust the clutch cable.

Causes:

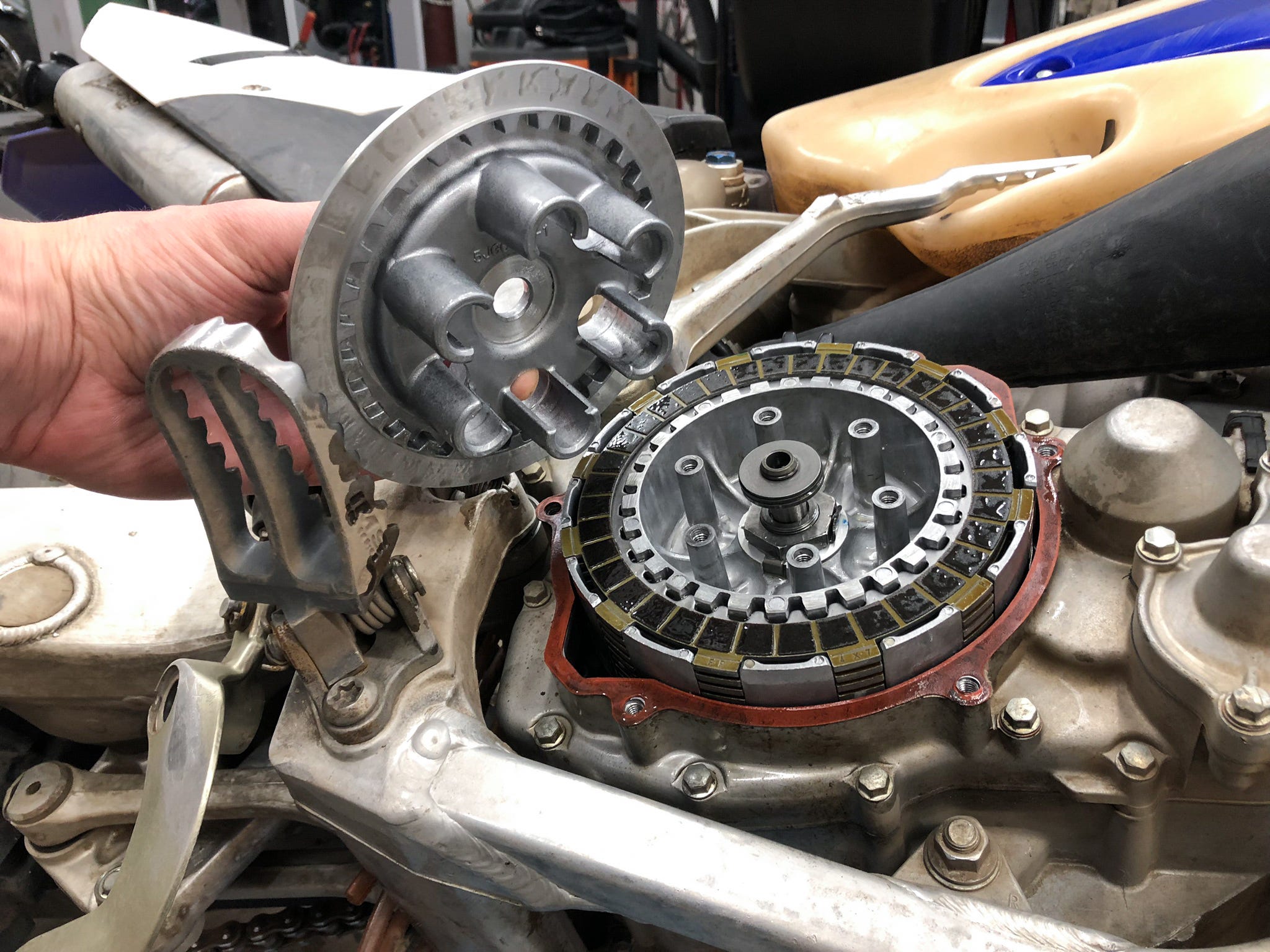

Do the sniff test. Pull the clutch cover off. If you smell burnt clutch material, chances are your clutch will need new components. The burnt smell is the result of the clutch heating up.

The parts that burn first are generally the friction plates. It’s a real obvious odor. You’ll know it when you smell it. Visually, you’ll see the heat marks in the drive plates. The friction plates can also become black in color. The best thing to do is check the plates dimensionally against the specifications in your owner’s manual. Make sure you’re within tolerance on width and flatness, states Sulecki.

Solutions:

For starters, you’re going to need to replace the oil. Be sure to pay close attention to the recommended service intervals in your owner’s manual. Doing so can extend the life of your clutch.

Sulecki adds, Fresh oil will help keep things lubricated and running cool. Oil does break down from heat and friction over time. In a lot of engines, the clutch shares oil with the transmission and valve train. Oil gets a lot of opportunity to break down quickly. Keep the oil fresh.

However, the damage of a cooked clutch cannot be undone. Clutch plates can warp over time from the heat. Warped plates cause the clutch to disengage unevenly and create all sorts of headaches. You will need to invest in new friction and drive plates, at least. However, heat could also damage the clutch springs, effecting spring tension. Be sure to inspect all your clutch components.

Sign #3: Feeling A Drag

Symptoms:

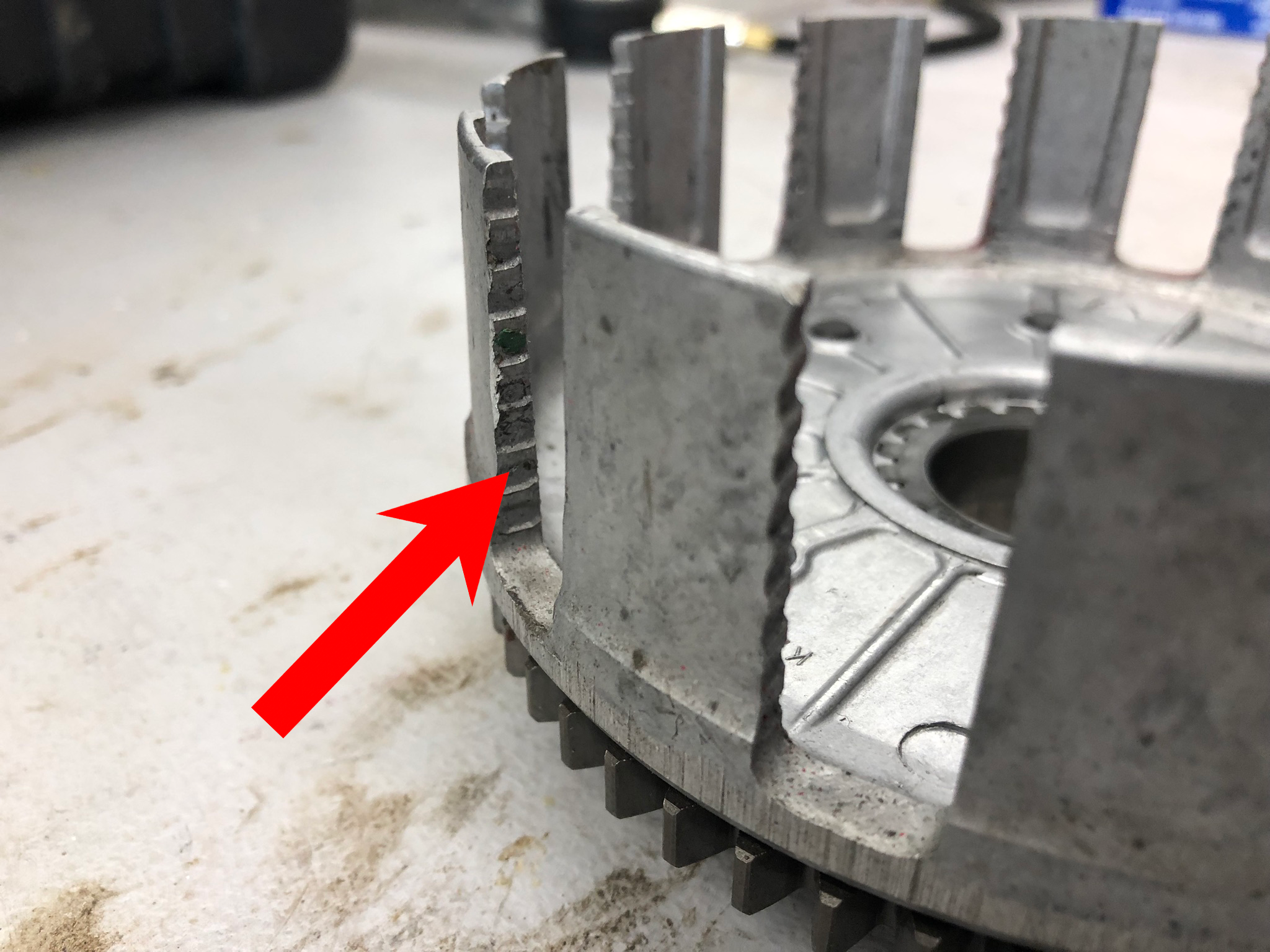

The clutch lever feels lumpy during clutch engagement/disengagement. Sometimes the lever can feel jerky. These are telltale signs that the clutch basket and/or inner hub is damaged and needs inspection.

Causes:

If your machine has the OEM/stock clutch basket, it was likely made using a diecast aluminum material. While fairly lightweight, durability is not stellar.

When you cast aluminum, you take molten aluminum and pour it into a mold. Once it has solidified, it gets processed from there into a finished part. When the material is molded it is generally not very dense. You get a lot of voids, porosity, inclusions, and imperfections in the material. The constituents inside the material aren’t bonded tightly against each other, states Sulecki.

Solutions:

There are a variety of aftermarket clutch basket options that use different manufacturing processes. Billet is a common alternative to casting, but even that has downfalls.

Sulecki explains, With billet, you’ll start with a cast piece of aluminum. It will generally get compressed a little bit in a forge press or some sort of pressure casting. That’s to condense the material a little tighter. Then the part is machined from the solid piece of metal. It has slightly better properties than a cast part, but not as much as a forged part.

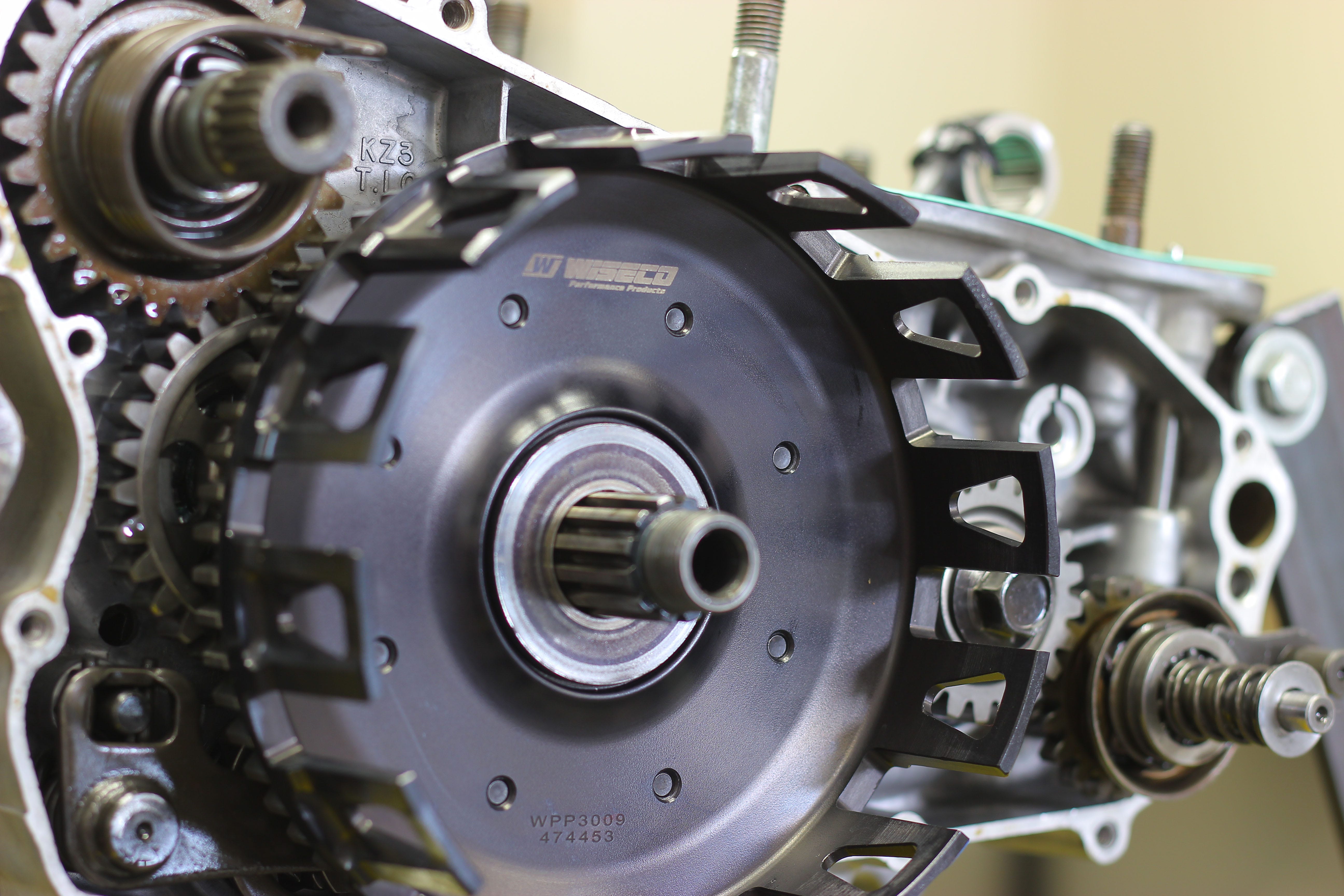

Forging is a very intricate and involved process. It begins with a cast and drawn bar of aluminum material, which is then smashed until all of the molecules are bonded to each other. This makes the material much denser and creates what engineers refer to as feature aligned grain flow. Basically all of the grains in the material are forced to flow up through the features particularly the tangs on the clutch basket and stanchions on the inner hub for greater strength. All of the material properties improve from tensile to fatigue to ultimate strength. Ductility is also improved, meaning the material can bend before it breaks.

Sulecki adds, The denser material is very resistant to impact and fatigue, which are two critical components of a clutch basket. Impact is caused by the clutch plates as they drive against the tangs on the clutch basket. Clutch plates will actually start to create indentations on a stock cast part, and dimples on a billet basket. In turn, the plates can’t slide smoothly across the width of the tab as you pull in the clutch lever to disengage the clutch. A forged clutch basket’s resistance to impact means that it will not develop notches in the tangs. Suffice it to say that forging is the superior material for clutch basket durability and lasting performance.

Check out all the technical details on Wiseco clutch baskets here.

To cap it off, Wiseco hard coat anodizes and coats their forged clutch baskets with Teflon. Hard coat anodizing aids in wear and abrasion resistance, as well as improves lubricity and corrosion resistance. Teflon coating is the last process. It helps fulfill the wear resistance and lubricity that Wiseco requires for their clutch baskets.

Find a Wiseco clutch basket for your machine here.

Lifetime Guarantee

It’s interesting to note that Wiseco has been manufacturing forged clutch baskets, pressure plates and inner hubs for years, but this all-too-important detail has flown under the radar. Our forged clutch basket is the best product we make that nobody knows about, says Sulecki. The performance-driven powersports magnate is so resolute in the durability of their forged clutch baskets that they offer a lifetime guarantee against notching and breakage. What does that mean? You’ll buy it once and never have to worry about it again.