Inside Engineering: The Science Behind Wiseco Racer Elite Pistons

Find out what makes the Wiseco Racer Elite pistons the latest in high performance piston technology.

Much of the aftermarket will tell you how great their new product is, how much better it is than everything else, and that you are missing out if you don’t buy it. What a lot of them fail to mention is why. Why is it better than the alternatives? How did the product get to its final point? How was the product tested and created to back up its performance and reliability claims? These are questions a lot of people fail to ask but should be asking when they are in the market for new Powersports performance parts.

The Racer Elite piston series is one of the latest additions to Wiseco’s high performance Powersports piston lineup. We’ve published some technical information on the features and benefits of these pistons, which can be read here. However, in this article, we are going to get further into the engineering and reasoning behind the creation of the Racer Elite pistons and how they bring such substantial performance.

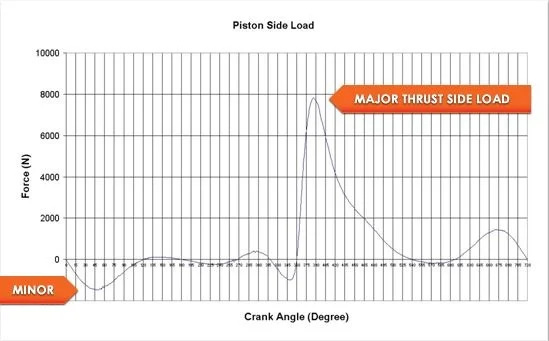

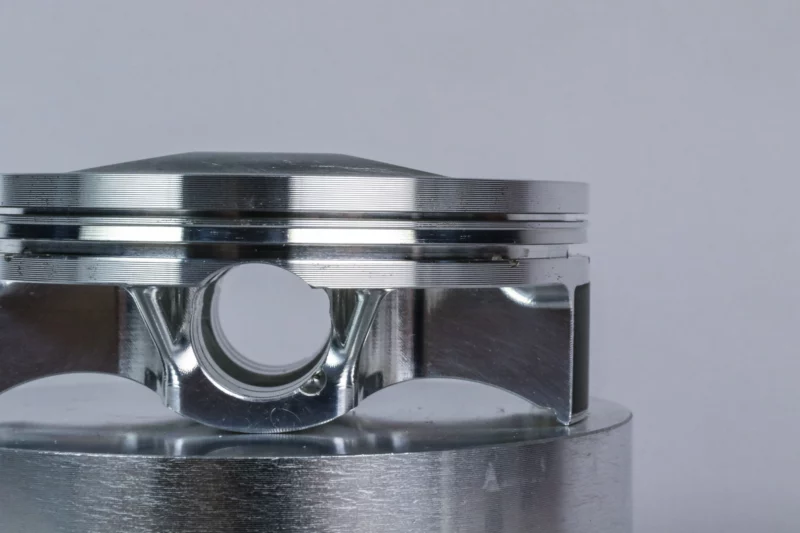

Notice the asymmetrical skirt design of this Racer Elite piston. Read on to learn about this design.

Asymmetrical Skirt Design

Perhaps the most unique aspect of the Racer Elite pistons is the asymmetrical skirt design. In basic terms, this simply means that one side of the piston skirt is not the same dimensions as the opposite side.

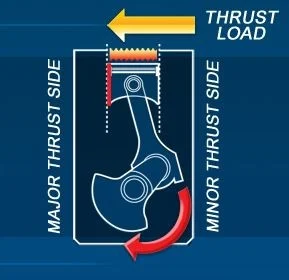

This illustrates the major thrust skirt of the piston in the cylinder.

Why make the skirts different sizes? Well, the reasoning behind the asymmetrical skirt design comes from the fact that pistons do not experience the same thrust load on all sides. The term thrust load refers to the force exerted on the side of the piston during the normal operation of 4 stroke internal combustion engines. The amount of load put on a piston during the intake and compression strokes is much less than the load exerted during the power and exhaust strokes. This is because during the power stroke, the compressed fuel and air mixture in the cylinder is ignited, forcing the piston down and onward toward the exhaust stroke. Because of this ignition, the force during these strokes can be many times higher than when not loaded by the force of combustion. The side of the piston that carries the greatest mechanical load is the major thrust skirt.

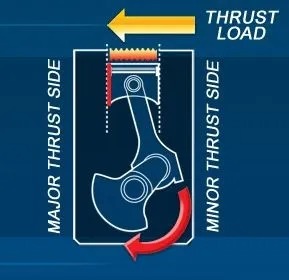

This diagram illusrtates the difference in piston thrust load on the major thrust side vs. the minor thrust side.

Therefore, the side of the piston that experiences this excessive load must have adequate skirt surface in order to maintain reliability. A lot of friction and load is created from high levels of force, so there must be enough skirt surface area to absorb it without compromising the integrity of the piston.

On the opposite side of the piston, where there is much less force and load, less skirt material can be utilized. With less skirt material, there is less friction, and the piston will be able to move more freely. This side of the piston, with less mechanical loading, is known as the minor thrust skirt.

Notice the difference in skirt sizes between the Wiseco Racer Elite piston (left) and the Wiseco Enhanced Pin Tower piston (right).

Asymmetrical piston designs aren’t a brand new concept; they just haven’t been utilized often in the Powersports industry until now. They have a fairly long history of being used in a variety of automotive professional race engines, including Formula 1, ALMS, and NASCAR, to name a few. While this type of design was hidden from the public, some auto manufacturers even started to pick up on using asymmetrical piston designs. The Wiseco Racer Elite pistons bring the asymmetrical skirt design to single cylinder Powersports engines.

Structural Design Maintaining Reliability

While the asymmetrical skirt design delivers great power and friction improvements, there must be other adjustments to the piston design.

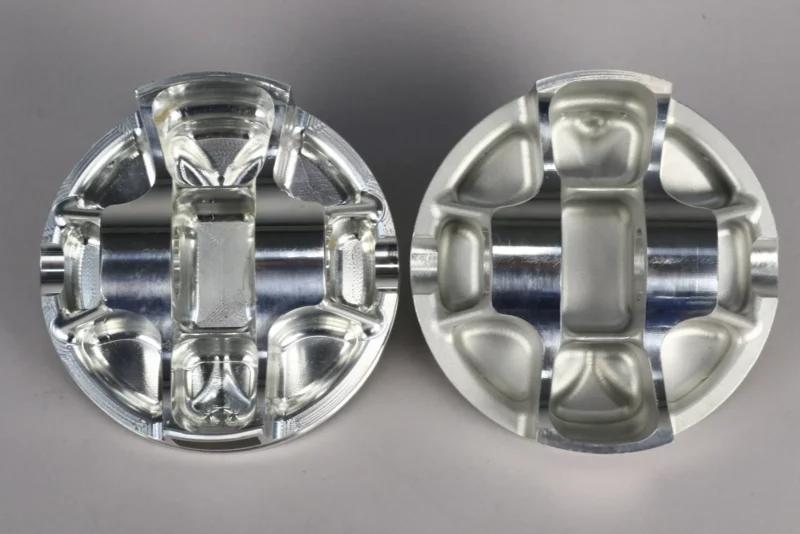

First, we must make sure that the piston maintains reliability. The extra performance would be useless if the piston couldn’t hold up to the stresses of high performance engines. Because there is less material on the piston skirts, a box and buttressed design is essential for the piston to maintain its shape and successfully diffuse the stress it encounters.

The reinforcing struts on both sides of the pin towers are key elements of the box and buttressed design. Unfinished (left) vs. finished (right).

Part of the box design on the Racer Elite pistons includes an enhanced pin tower. The pin tower was designed to be both taller and thicker than pin towers on standard pistons for similar applications. If you hold the piston upside down in your hand, you’ll notice that each of the pin towers themselves are wider, as well as having more material surrounding the pin bore, and include struts reaching toward the edge of the piston for extra stability.

Here’s a Racer Elite piston only partly machined. Machining of the reinforced undercrown takes place first, then the crown and ring grooves are taken care of.

Another issue that might come to mind with asymmetrical skirts is the balance of the piston. Naturally, when one side of piston has more material than the other, the piston weight will not by symmetrical, or evenly distributed front to back. Wiseco addressed this by machining each Racer Elite piston with a balanced center of gravity. This allows the piston to maintain balance, which helps the piston remain stable and quiet, and also maintain proper ring seal.

Design, Development, & Testing

Powersports asymmetrical pistons have been long in development, well before the concept was finalized. As with all new piston designs, Wiseco engineering began with 3D computer design. Multiple virtual designs were created, and initially tested using finite element analysis (FEA), which consists of testing the design against hypothetical thermal and mechanical stress loads. This testing and analysis allows engineers to tweak designs, and make fine adjustments to each area of the piston, until the design performs well enough to be machined into an actual prototype piston. All of the Racer Elite prototypes were billet aluminum, just as the final products are.

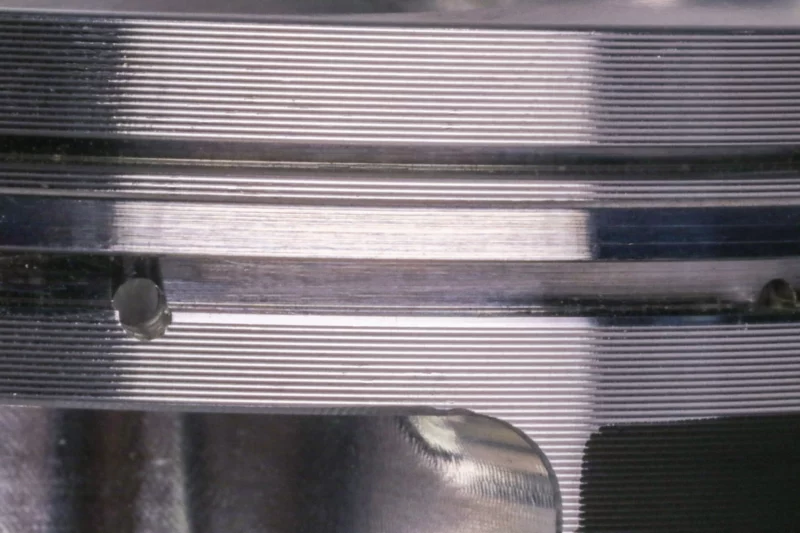

An up close look at a the CNC machine work done on this Racer Elite piston still in the making.

The next step is for the prototypes to be installed in an engine and dyno tested. The pistons are tested with a breadth of different engine conditions, including high RPMs, heavy load, and extended operation time. Any shortcomings or unsatisfactory performance of prototypes brings the engineer back to the computer design to make adjustments, and then machine a new prototype.

A Racer Elite prototype being machined after passing its FEA tests.

This design and testing process led Wiseco to have asymmetrical Powersports piston designs for multiple different engine platforms perform very successfully. The end product, the Racer Elite pistons, boast lightweight, strong durability, and great performance gains via lowered friction and higher compression.

Piston Groove & Ring Design

The asymmetrical design isn’t the only design aspect that allows the Racer Elite pistons to perform so successfully. Ring grooves on the Racer Elite pistons are CNC precision machined to ensure the highest level of flatness and size tolerances. The flatness and angle of the ring groove is important to allow the piston ring itself to seal compression and control oil properly and efficiently.

The angle and flatness of the piston ring groove is equally as important as that of the compression ring itself to ensure efficient ring seal and oil control.

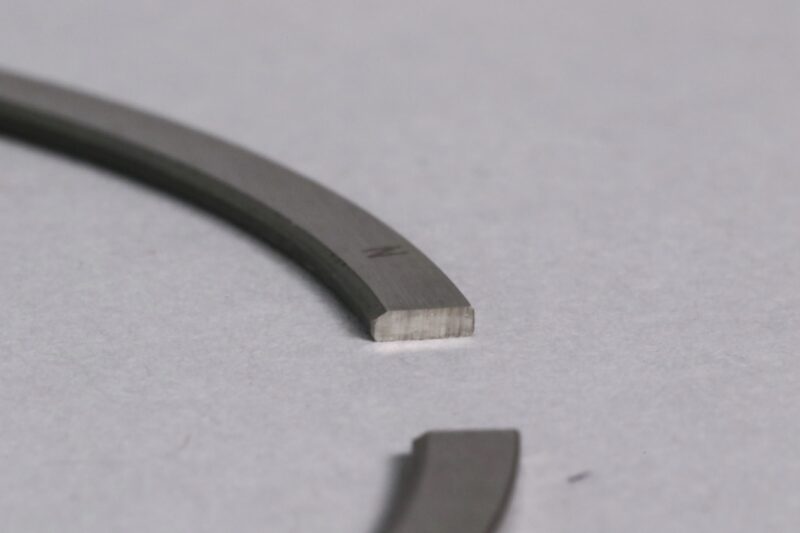

The compression rings used on Wiseco Racer Elite pistons are another key feature not commonly seen in Powersports applications. The rings are very thin width, which help assure bore conformability, and are gas-nitrided for improved wear and sealing capability. These unique piston rings also incorporate what is known as positive twist geometry. In simple terms, this means the top inside edge of the ring has a bevel cut into it, which allows the ring to twist slightly upward on the outer edge of the ring face. This type of ring can better seal cylinder pressure, while also sealing the bottom of the ring to the ring groove during the compression stroke. The twisting nature of the ring allows the bottom corner of the ring face to remove oil from the cylinder wall on the down stroke of the piston, both sealing compression, and acting as an oil control ring.

The bevel cut into the top inside edge of the ring gives it positive twist geometry.

In addition to the unique ring geometry, the Racer Elite compression ring has a precise fit in the ring groove. This is accomplished by lapping the side of the ring to match the ring groove through a proprietary lapping process. Generally, lapping involves using an abrasive metal compound to slightly cut into the metal of the surface you are lapping. The result is extreme smoothness and flatness, by removing any subtle surface irregularities and imperfections.

Wiseco Global Product Manager Dave Sulecki comments on the Racer Elite ring lapping: “This technology is common in NASCAR and Pro Stock drag racing…commonly use a lapped ring to a precise ring-groove fit, and we’re introducing this technology to Powersports.

Wiseco’s propietary lapping process removes imperfections on all surfaces of the compression ring, leaving ultimate flatness for better ring seal.

That solution by itself will increase ring seal and horsepower over a standard design, continues Sulecki.

The result of this process is a clearance between the axial height of the groove and the ring of less than .001 inch (for reference, a human hair is typically around .001). Thanks to this strict attention to detail, blow-by has been significantly reduced during Racer Elite testing, keeping the air-fuel mixture in the combustion chamber where it belongs, leading to more horsepower.

Low Friction Coatings

Low friction features were also added to the Racer Elite pistons to complement its design features. The piston skirts are coated with Wiseco ArmorGlide skirt coating, which is a proprietary coating that stays on the skirt for the life of the piston. The coating is a dry-film lubricant made from molybdenum disulfide (or moly). It is precisely screen printed onto the pistons skirts in order to not affect the piston structurally, as different high heat application processes might. It reduces friction during operation, as well as provides quieter operation by reducing piston rock.

A piston on the ArmorGlide tooling after a fresh skirt coating was applied.

Read more about Wiseco’s many proprietary piston coatings here.

The Racer Elite pistons also come with a DLC coated wrist pin. DLC (Diamond-Like Carbon) coated pins provide smoother rotation of the pin in the pin bore, as well as the small end of the pin itself. DLC coatings are very resistant to wear thanks to their friction and heat reduction, so they help the Racer Elite pistons operate smoother for longer.

Find Racer Elite and all other Wiseco products for your machine here.

100% CNC machined billet aluminum, from raw to complete.